- Details

- Hits: 1997

Article: Iron Ore Haul from Stambaugh Complicated Business for C&NW - 1955

By Jean Worth, Escanaba Daily Press - November 5, 1955

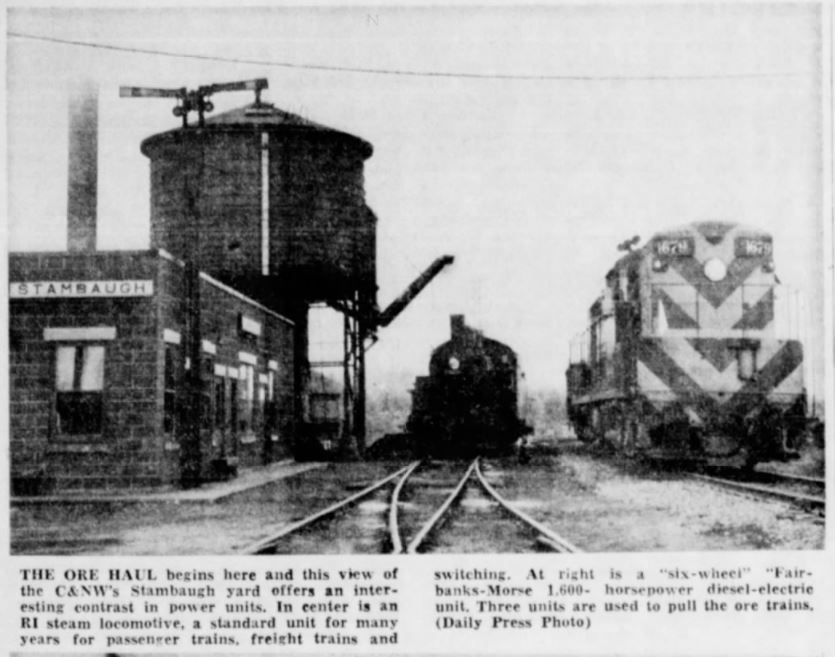

The ore trains used to run up to 30 miles an hour, but the speed was less efficient than today's slower operation. The diesel locomotive has revolutionized ore haul in the Upper Peninsula, just as it has revolutionized railroading throughout the United States. Type J steam locomotives once pulled trains of 85 loaded ore cars in the U.P. and later big J-4 steam locomotives pulled 105 cars. Today no ore moves under steam power in the Upper Peninsula.

Joint Operation

The ore haul to Escanaba has been a joint cooperation of the C&NW and the Milwaukee Road since 1936, when the roads signed the Menominee Range Ore Pool Agreement, which ended their competition and duplication of services in the area. The Milwaukee Road was doing 34 percent of the business at the time and the C&NW 66 percent and they now share the ore haul in those proportions. The arrangement keeps four employees in the Escanaba office of the C&NW doing little else but accounting for the roads' proportionate shares of pool expenses and income.

The orange diesels of the Milwaukee Road add to the green and yellow diesels of the North Western move over the same rails, interchange crews, share expenses and earnings.

Start at Palatka

To learn how ore is moved overland I climbed up into the cab of the lead diesel unit of a 124-car ore train at Palatka, where the train was assembled. I had never heard the name before. It is a rail yard outside Stambaugh on the Menominee Iron Range.

Ahead, the route sheet showed were Scott Lake (Saunders), Pentoga, Naults, Stager, Ridgetop, Florence, Hematite, Spread Eagle, Antoine (Iron Mountain), Cornell Mine Switch, Cuff Siding, Wells Spur, Siding No. 5, Appleton Mine, Sturgeon, Leapers, Siding No. 4, Oro, Kirby's Spur, Siding No. 2, Tesch, No 6 Ore Yard and the big red ore dock on Little Bay de Noc at North Escanaba.

Beauty Along The Way

Most of these names appear only on the C&NW's operating timetable. The signs along the route denote old mine locations, long gone sawmills and settlements, spur tracks, communities and sometime, seemingly, just a railman's need for a sign board.

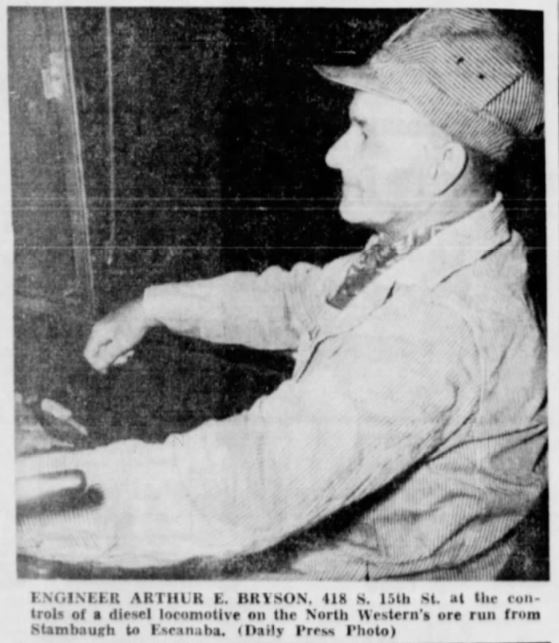

Most of the route is in forest and there is beauty all along the way and the sight of wildlife is commonplace. "We see deer almost every trip," said Engineer Arthur E. Bryson of Escanaba. "Not long ago we had a bear running down the track alongside the train. He hit 22 miles an hour and kept it up for quite a way." Fireman August Hartwig of Escanaba nodded agreement.

The haul from the Stambaugh-Iron River area down to the flatlands of Menominee County is one of constant change in power, up-hill and downhill. The ore trains use what is called the Schlesinger Line, built by a capitalist who visioned an industrial empire in which he would own mines, railroad, lake vessels and steel mills. The line is now owned by the C&NW and it and the Milwaukee Road use it for a one-way ore haul to the lake, returning the empty cars by the regular freight and passenger line to the south, via Powers - Spalding and west through Iron Mountain.

Average Train 125 Cars

U. P. ore trains have had as many as 150 cars, but the average number for a train is now 125, carrying about 11,000 tons of iron ore. Lake vessels which load at Escanaba take from 8,000 to 16,000 tons of ore and average 10 to 11 thousand. The ore train diesel power units - three to a train -- could pull more loaded cars, but the draw bars and couplings of the cars might break under the strain, even with the expert gentling that diesel locomotive engineers use in handling the trains. They move them cautiously over the tops of grades, but even with such caution they sometimes break into two.

Diesel operations started on the CNW ore haul in the Upper Peninsula in 1950, when six units were bought to operate two trains. These diesel units weren't as powerful as those in use today and they hauled 110-car trains. The diesels now in use are called six-wheelers, but they have six wheels on a side, or 12 in a unit. Each axle has its own traction motor, six in all, and together they generate 1,600 horsepower per unit.

Engineers Are Veterans

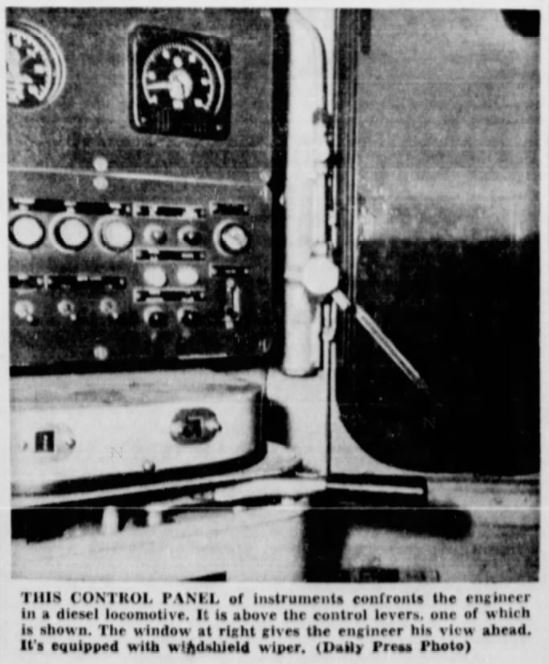

The diesel units are really diesel-electric. The big diesel motors are coupled by shafting to electric generators which operate the traction motors on the axles. Dynamic brakes are used, a device which changes the electric currents so the motors become generators and work to slow the wheels.

Besides the dynamic braking on the diesel units, there are air brake systems on the diesels and the ore cars. The air is bled out of the line to release the brakes and if the brain breaks in two, the brakes are set automatically. It takes time for the brake release to progress to the end of long ore trains - it works about as fast as a bicycle can be ridden - and if the engineer works the power before all the train is braked, the train breaks in two.

Slack In Train

There is a lot of slack in a train; the front diesel unit goes 75 feet before the hind end of the train moves. "You've got to have a little judgment," said Bryson "or the end of the train doesn't move at all".

"I can't think of any freight in the country as heavy to haul as iron ore. We'll carry 11,000 tons in a train. We had a pileup over a broken rail at Ridgetop on October 1 an when I looked back those cars were still coming over the hop of the heap."

The ore haul is one of the North Western's most lucrative businesses and turns in the largest profit of any commodity handled by the line. The freight bill for an ore train is about $10,000. That isn't all profit, of course. There are five man pool crews on the big trains and pay is geared to the number of cars moved. The diesel locomotive cost about $1,000,000 for four units and the ore cars for a full train cost nearly three quarters of a million.

Complicated Assembly

But after labor and equipment costs, there are the savings that come from handling full train lots and there aren't damage claims against the road, except in case of wrecks like the one at Ridgetop, which cost about $50,000. The diesel equipment requires expert operations and mistakes ae costly. It costs about $6,000 to replace a traction motor.

The ore haul is not a simple matter of taking cars from mine sidings, assembling them into trains and pulling the trains to the lake head. The ore delivery is a complicated business. The railroads act as mine-mixers as well as haulers in the ore trade. They mix the ore they haul for the furnace companies; load vessels so they deliver an ore batch of the chemical analysis desired for steel making. To do this the C&NW holds approximately 1,000 cars of ore every day in its Escanaba yard. Often steel companies hold a boat being loaded until the arrival of certain ore which are enroute, although hundreds of cars of other types of ores are on hand.

Ore Analysis Varies

The Gogebic Range ore haul has slacked from its summer volume and at present time about a cargo a week is being moved out of Escanaba. By the end of the ore shipping season the Escanaba dock will have handled about a million tons of Marquette Range ore, a larger-than-usual volume which results from the build-up of steel making in the Chicago area. The Escanaba dock's total shipments for this season will be near six million tons. The average is 4.5 million.

Rail-Lake Relation

Economics control ore movement. The Chicago steelmaking buildup is changing the pattern of U. P. ore shipment. It has resulted in the decision of the Lake Superior & Ishpeming Railroad to move some Marquette Range ore over its line to Eben Junction, then over the Soo Line to Rapid River, and to build an LS&I short line and an ore dock there to load lake vessels for the South Chicago haul. [Editor's note: The ore dock was never built].

It costs the same amount to move Gogebic Range ore overland by rail to Ashland, Wis., on Lake Superior and haul it by water to Indiana Harbor, Ind., as it does to move it the greater distance by rail to Escanaba for Lake Michigan loading. It takes 24 hours for the trip from Escanaba to Indiana Harbor, or 60 hours for the round trip, including six hours for loading and 8 to 10 hours for unloading. This 60 hours contrasts with almost six days for the Indiana Harbor-Ashland trip. Boats on the Escanaba-Indiana Harbor run can make almost twice as many trips in a season.

More Trains Daily

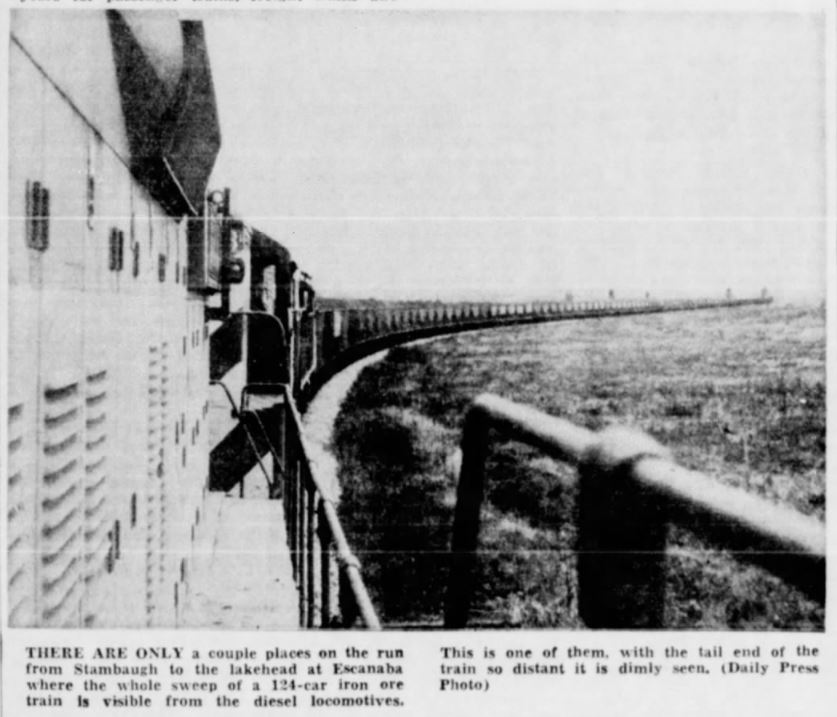

Engineer Bryson, a veteran of 42 years service with the North Western, says that trainmen like the new diesel units better than the old steam locomotives. The cabs are comfortable and there's no coal to shovel. The diesel engineer is busy on the Iron Range, accelerating and braking, sanding the track so his driving wheels won't slip and flatten. The track ahead is watched and the train is watched. The train is so long and curvatures of the track are so frequent that only in a few places on the 105-mile run from Stambaugh to Escanaba can person in the cab look back and see its entire length.

Bibliography

The following sources are utilized in this website. [SOURCE-YEAR-MMDD-PG]:

- [AAB| = All Aboard!, by Willis Dunbar, Eerdmans Publishing, Grand Rapids ©1969.

- [AAN] = Alpena Argus newspaper.

- [AARQJ] = American Association of Railroads Quiz Jr. pamphlet. © 1956

- [AATHA] = Ann Arbor Railroad Technical and Historical Association newsletter "The Double A"

- [AB] = Information provided at Michigan History Conference from Andrew Bailey, Port Huron, MI