- Details

- Hits: 2284

Article: Saginaw & Bay City Railway & Light Co. - 1905

From the Street Railway Review, June 15, 1905

A syndicate controlled by Hodenpyle, Walbridge & Co. of New York, and E. W. Clark & Co., of Philadelphia, has recently obtained control of the following properties in Michigan: Saginaw Valley Traction Co., Bartlett Illuminating Co., Saginaw City Gas Co., Bay City Traction & Electric Co., and Bay City Gas Co. These separately incorporated companies are now merged into the Saginaw & Bay City Railway & Light Co., and are operated by one management, with general offices in Saginaw and a branch office in Bay City. The operating officers are: H. D. Walbridge, president; B. C. Cobb, vice-president and general manager; C. E. Mershon, secretary-treasurer; M. S. Hopkins, Columbus, Ohio, consulting engineer; J. C. Young, general superintendent; H. C. Morris, Bay City, superintendent.

At the time of consolidation each of the properties was operated independently, having its own management and generating station. These electric lines comprise the city systems in Saginaw and Bay City and an interurban line, 13.54 miles long, connecting these cities. These properties have been united and their four power stations superseded by two new ones, which now supply current for operating all the cars and for lighting the city of Saginaw and a portion of Bay City and its suburbs.

City Systems

The city system of Saginaw comprises 22.7 miles of single and double track lines, including a suburban branch to the company's Riverside Park. The lines in Bay City comprise 17.5 miles of single and double track, which includes a 5-mile suburban branch to the company's Wenona Beach Park. Since the syndicate obtained control a large portion of the lines in both cities have been rebuilt. Sixty-pound T-rails of the A.S.C.E. section are laid on oak ties bedded in concrete. The joints are bonded with No. "oo" American Steel & Wire Co.'s concealed, expanded terminal bonds. This construction is the standard for unpaved streets in both Saginaw and Bay City. In paved streets a Shanghai rail 6 in. high, having a T section and weighing 60 lb. to the yard is used. This rail is spiked to oak ties laid in a concrete bed. specially notched gauge brick are used. Throughout the cities, new special work with hard steel centers has been laid. The overhead work is of the latest type, using wooden and steel poles for span wire construction.

The operating schedules on the different lines in the two cities furnish 5, 10, and 15-minute headway. For this service there are required for winter operation in Saginaw 23 cars and in Bay City 18 cars. The summer schedules have an increased number of cars to suit the patronage. The Saginaw equipment includes 36 convertible cars of 8, 10, 13 and 15 bench types, also 32 closed cars having varied lengths of 16, 22 and 28 ft. The Bay City equipment includes 29 convertible cars and 25 closed cars.

Interurban Line

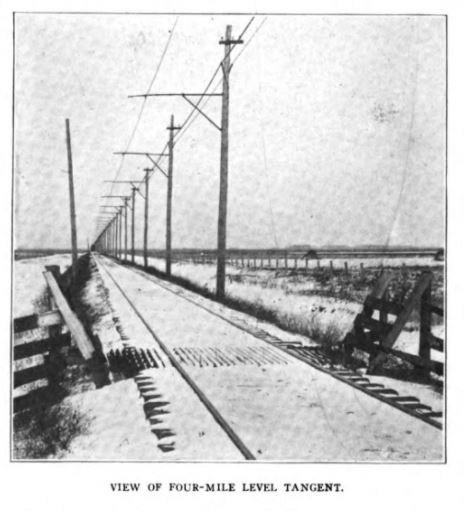

For a distance of 1.61 miles the interurban cars operate over city tracks in Saginaw; for a distance of 2.57 miles the track is on one side of the highway; for a distance of 5.90 miles the roadbed is build on a 100-ft. private right of way and in Bay City the interurban cars traverse 3.26 miles of city tracks to reach the center of the city. Between the limits of the two cities the track and roadbed are built according to steam railroad standards, the private right of way portion of the line having a level tangent four miles long built as a 7-ft. fill across the river marsh. This right of way is enclosed by woven wire fencing.

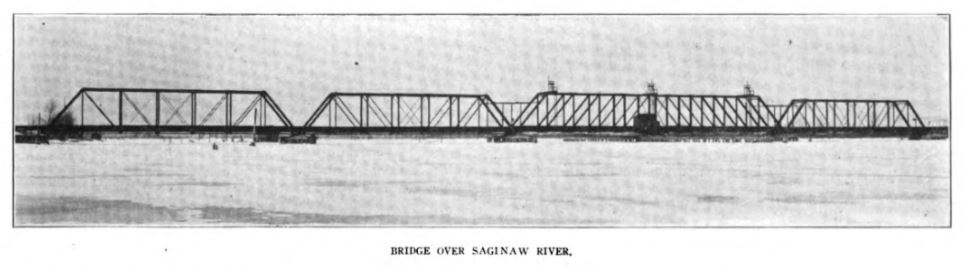

About half way between the two cities, the line crosses the Saginaw River on a single track, four-span, through truss bridge, 2,000 ft. long, with one panel built as a draw span. This interurban line parallels the Michigan Central and the Grand Trunk tracks on the west side of the river, and the Pere Marquette tracks on the east side of the river.

The working conductor is a No. "ooo" single trolley wire, suspended on flexible brackets. Thirty-five-foot cedar poles are used. Other than the overhead construction, the poles carry the company's telephone line and the direct current trolley feeders. These feeders consist of a 250,000 c.m weather-proof cable, which extends 4 1/2 miles north from Saginaw and is only tapped to the trolley line at its extreme end, and another feeder of 500,000 c.m. cross-section, which connects the Saginaw and Bay City power houses and is tapped to the trolley wire at frequent intervals. This places in parallel the two generating stations at the ends of the line and assures an equalization of the loads. The present reconstruction plans include a 10,000-volt high-tension transmission line, which will be carried on the interurban poles and will connect suitable apparatus in the two stations at the ends of the line, so that in event of engine or generator trouble all the load may be carried by either one of the stations.

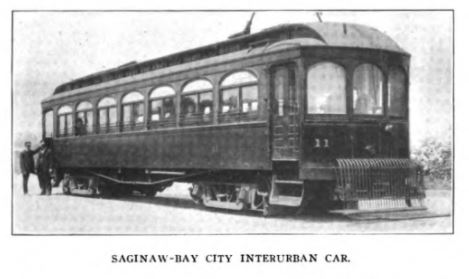

The winter schedule on the interurban line, operating under 40-minute headway, requires three interurban cars, and the summer schedule has a 30-minute headway with added cars as traffic demands. A freight train making three trips each way every day handles all classes of freight and express. there are freight receiving depots at both ends of the line and the steam railroad freight rates are met with the same classification.

Until the completion of the new power station at Saginaw the interurban feeders were supplied with current from a power station in Carrolton, on the Saginaw River, just north of Saginaw. This station had generating capacity of 950 k.w. of railway units and 1,150 k.w. of lighting units. At Carrolton, adjacent to this power station, are the repair and storage barns for the interurban cars and the office of the interurban dispatcher.

Saginaw Barns and Shops

A new barn and shop building is now nearly completed and will soon be able to care for all the Saginaw city cars. This building is made up of the old barn and a new addition, the combined building having dimensions of 240 x 260 ft., and being bounded on three sides by streets, the tracks extending through the building from street to street. The walls of the building are of sand-lime brick. The roof, supported by wooden trusses resting on the brick partitions and walls, is fitted with numerous skylights for lighting the separate sections of the building. The floors are concrete, except in the machine shop, where they are made of heavy planking, and in the storage portion, where cinders are used. The entire front of the building is enclosed by Kinnear rolling steel doors with the vertical posts hinged at the top, so that when the doors are open the intervening posts may be drawn up against the ceiling and added clearance given for handling long interurban cars around the special work at the entrance to the barn.

The old portion of the barn will be used for storage. Here there are eight tracks and a transfer table, all in one bay, which will furnish accommodations for 32 city cars. The front part of the old building has two stories, which are used for the offices of the superintendent of transportation and his assistants, and as locker and reading rooms for motormen and conductors. The fireproof wall that extends throughout the length of the building between the old and new portions is pierced by but one opening, and this is protected by fireproof doors.

The main bay of the new portion has eight tracks extending through the building. Two of these tracks at one end of the building will be arranged with the proper drainage and appliances for car washing, and under two other tracks for a length of 150 ft. are inspection pits. This bay will accommodate 40 cars.

Adjacent to the main bay and separated from it by a fireproof wall is the machine shop. This shop has three tracks the length of the building, with a pit which extends through the central portion of the room and is eight feet wide, the rails being supported on oak stringers and posts. At the rear of the machine shop is the paint shop, through which two of the machine shop tracks extend. this shop is separated from the rest of the building by brick partition and the openings over the tracks are closed by steel doors. The paint shop is lighted by two rows of skylights, one over each of the tracks, and the floor is of concrete, sloped for the proper drainage, so that the cars received here for painting may first be washed.

The south by of the building comprises the several small shops and that portion of the repair shop using machine tools. The front end of this bay is divided by brick partitions into several office rooms. Adjacent to this portion is the armature room. 24 x 36 ft. which opens by a double door into that part of the machine shop fitted with working tools, which part is 75 x 30 ft. in size. In this room are two lathes and one drill press, emery wheel, power hack saw, shaper, bed plane, wheel press and wheel boring mill. These are arranged into rows with a center aisle, and are driven by a 15 h.p. 500-volt motor. Adjacent to the machine shop is the blacksmith shop, 20 x 28 ft. Next to this is the stock room. 26 x 40 ft. in size, and the remaining portion of the south bay, 25 x 75 ft. in size, is the carpenter shop.

The two portions of the machine shop are equipped for handling repair work with an overhead pneumatic hoist system. Over each of the two south tracks is hung an I-beam, the lower flanges of which support the carriages of pneumatic hoists. Another I-beam extends over the aisle between the two rows of machine tools, and over the machine shop pits is an I-beam trackway built in the shape of a circle, so that parts may be readily transferred from any of the three repairs tracks to the machine tools. There are eight pneumatic hoists, four of which will suffice for lifting a car from the trucks and the other four will be used in the repair work on the trucks, motors, etc. These hoists are the product of the Northern Engineering Works, of Detroit, Mich., and will be supplied with compressed air by a horizontal compressor manufactured by the Chicago Pneumatic Tool Co., driven by a G.E. 20-h.p. 500-volt motor. At this shop will be centralized the repair work of the entire Saginaw city lines.

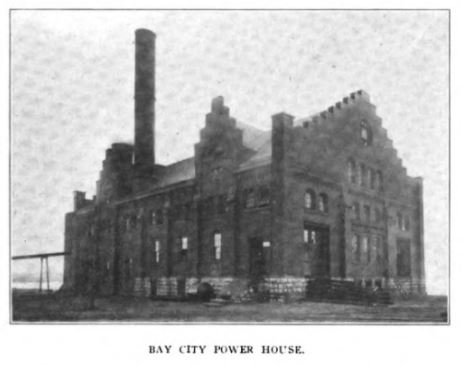

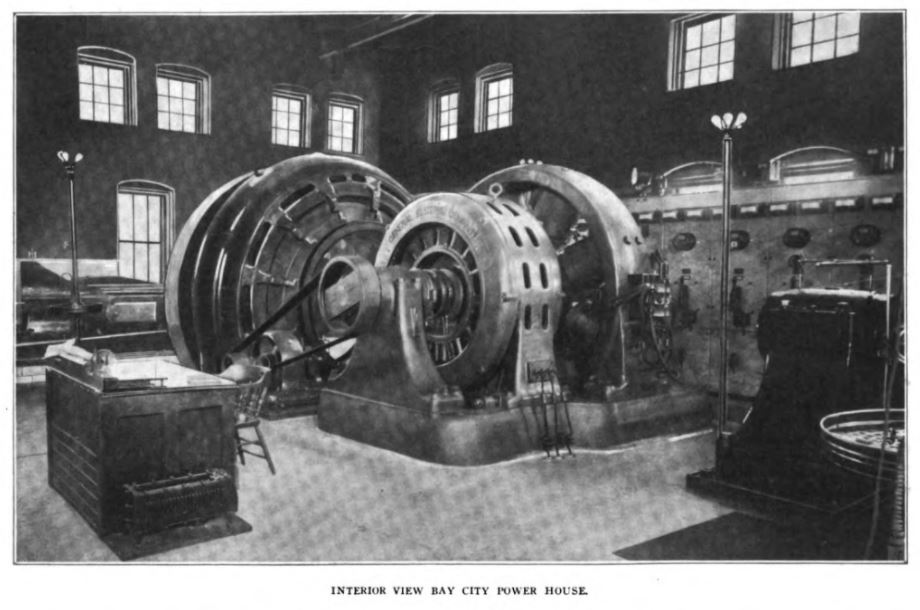

Bay City Power Station

Local coal and sawmill refuse are burned under the boilers. The coal is unloaded from the steam railroad cars into the hopper of a steel cable coal conveyor operated by a 15-h.p. direct current motor. This conveyor distributes the coal into an elevated storage bunker built along the river side of the boiler room, from where the coal falls to the boiler room floor in front of the boilers. This bunker has a capacity of 200 tons. The boiler equipment consists of three Sterling boilers, one 500-h.p. and two 230-h.p., generating steam at 150 lb. pressure. There are two stacks, the natural draft stack is 70 ft. high with a diameter of 70 in., and the induced draft stack is 50 ft. high with a diameter of 90 in. Green economizers are used, there being 40 standard sections built at the rear of the boilers. The induced draft is maintained by two Sturdevant fans, 10 ft. in diameter and driven each by a 10 x 10-in. Sturdevant engine. Each boiler is equipped with an Eames differential draft gage, manufactured by the Appliance Manufacturing Co., Chicago.

Water for the boiler feed is metered by Keystone hot water meters, and is pumped by one Worthington outside packed pump and one Hughes duplex plunger pump. Cochrane feed water heaters are used to raise the temperature of the boiler feed to the boiling point before it is fed into the drums. A neatly arranged board for watching the temperatures of the economizers is equipped with pyrometers on the water intake and outlet for the economizers and on the intake and outlet of the economizer gases. A Bristol recording draft gage is also mounted on this board.

There are two main generating units, each consisting of a 500-kw 600-volt Siemens & Halske direct-current generator, direct connected to a Russell tandem-compound horizontal engine with cylinders 22 in. and 40 in. in diameter and a 30-in. stroke. These units operate at 120 r.p.m. The exhaust steam is condensed and a vacuum maintained by two sets of Laidlaw-Dunn-Gordan jet condensers with 14 x 18 x 24-in. pumps. Each engine receiver is protected by two safety valves, one 3 in. and one 1 1/2 in. in diameter, set to open at 35 and 34 lb. respectively. A gravity oiling system is used for lubricating all bearings, and the cylinders are oiled by lubricators fitted with hand pumps for filling.

Between the main direct current generators is a G.E. 350-kw motor-generator set with a belted exciter. The motor of this set takes direct current from one of the main units and drives a 2,300-volt 3-phase alternating current generator, the output of which is used for commercial lighting in Bay City and for street lighting in the suburb, Essexville. It is by means of this unit and a similar one in Saginaw, with their sets of transformers, that in event of a disorder to the direct current units in either station, continued operation of the car lines will still be possible by reversing the usual operation of these motor-generator sets and thus making the damaged power station a substation of the one whose generating units are operating. The regulation of the voltage generated by the alternating current part of the motor-generator set is effected by means of a Type-TA voltage regulator, which so short circuits the field resistance of the exciter that the field current in the generator remains steady but varies in amount to suit the load. This motor-generator set has its capacity supplemented by a similarly connected set consisting of a 200h.p. G.E. 575-volt motor direct connected to 120-kw, 2,300-volt, 3-phase generator.

There are two switchboards for controlling the output of this station, one at each end of the engine room and between the two generating units. The board for controlling the railway output consists of nine panels of black slate fitted with Westinghouse instruments and with recording ammeters and voltmeters on the battery circuits, also a recording wattmeter for measuring the output of the entire station and an illuminated dial voltmeter mounted on a swinging bracket at the end of the board. The lighting board, which is at the opposite side of the room, consists of 10 blue marble panels and is of the General Electric Co.'s make. There are panels for the control of the input and output of the motor-generator sets and feeder panels for the city lighting circuits and for the street lighting circuits, which feed through hub transformers to the arc lights in Essexville One each of these alternating current feeder panels is an ammeter, voltmeter, recording wattmeter and an oil-break switch with overload trip. Above the center of the board, mounted on a pivoted bracket, is a synchronoscope, and at one end of the board, mounted on a swinging bracket, is a set of ground detectors.

The engine room and its included apparatus and machinery are served by two sets of differential blocks, each of three tons capacity. Each of these sets consists of a block suspended from a trolley which travels along the lower flanges of an I-beam, suspended by similar trolleys at its two ends from two other I-beams, one resting on the end wall of the room and the other spanning the middle of the room directly under the center of the roof trusses. With this arrangement the differential block can be placed over any piece of apparatus in its half of the engine room and as there are two similar sets the entire apparatus is thus served.

Bay City Car Barn and Shop

Near the power house is located the car barn and shop for the repair and storage of the Bay City local cars. This building is of red brick with a roof supported by wooden trusses and consists of three main bays. The west bay, 30 x 250 ft. in size, has one track extending its entire length. The front portion of this bay is used for offices, rest rooms and for a stock room. The rear of the stock room is the machine shop, in which there is a pit 60 ft. long under the track. The middle bay of the building is 244 x 250 ft. in size. The two tracks have pits under them, extending half the length of the building. The paint shop is in this bay. The other portion of the building is 50 x 250 ft. in size, and has four tracks with pits under each of them. This portion of the building is used for storage.

Parks

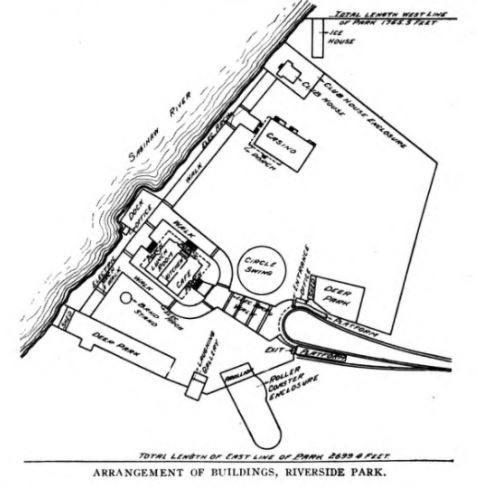

Up the Saginaw River from the city of Saginaw, a distance of three miles, is the company's Riverside Park, the general plan of which is shown by the accompanying illustration. The casino in this park, in which is produced a continuous vaudeville performance, has a seating capacity of 1,500 persons, and is operated in a similar manner to the Wenona Beach Park casino. This park has a large number of the usual entertainment features. Both of the company's parks are operated by a park manager, who reports to the general manager of the combined properties.

Bibliography

The following sources are utilized in this website. [SOURCE-YEAR-MMDD-PG]:

- [AAB| = All Aboard!, by Willis Dunbar, Eerdmans Publishing, Grand Rapids ©1969.

- [AAN] = Alpena Argus newspaper.

- [AARQJ] = American Association of Railroads Quiz Jr. pamphlet. © 1956

- [AATHA] = Ann Arbor Railroad Technical and Historical Association newsletter "The Double A"

- [AB] = Information provided at Michigan History Conference from Andrew Bailey, Port Huron, MI