- Details

- Hits: 1343

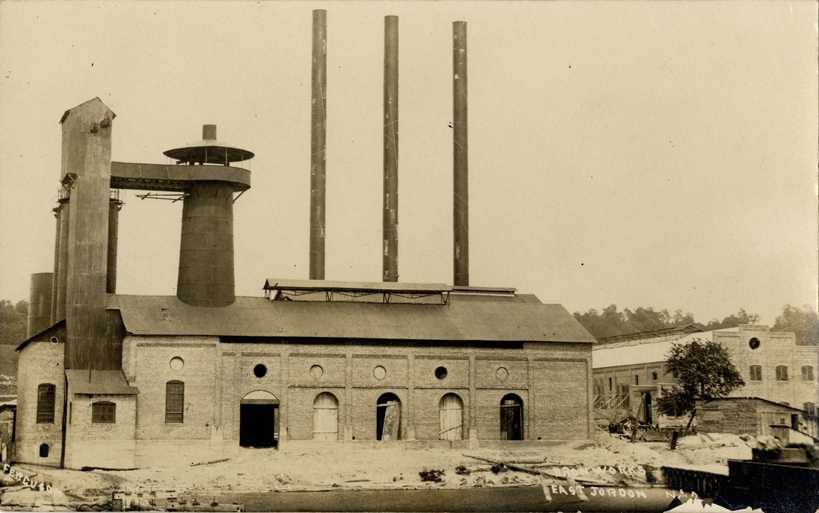

Location: East Jordan, MI - East Jordan Furnace Company

The East Jordan Furnace Company was organized in Michigan, November 24, 1909, with a capital stock of $375,000.00. Its officers are Charles H. Schaffer, President; F. B. Baird, Vice President; and W. J. Ellson, Secretary and Treasurer. The furnace is located at East Jordan, Michigan, on the Detroit and Charlevoix, and East Jordan and Southern Railroads.

The East Jordan Furnace Company was organized in Michigan, November 24, 1909, with a capital stock of $375,000.00. Its officers are Charles H. Schaffer, President; F. B. Baird, Vice President; and W. J. Ellson, Secretary and Treasurer. The furnace is located at East Jordan, Michigan, on the Detroit and Charlevoix, and East Jordan and Southern Railroads.

Photo Info: An early photo of the East Jordan Iron Works. [Detroit Public Library Collection]

Notes

A large portion of the plant came from Principio, Maryland. A plant had at one time been in operation at that point making charcoal pig iron, but because of market conditions and the failure to have at hand a supply of charcoal it had to be abandoned. It was bought en masse by Michigan parties and moved to East Jordan.

The height of the furnace is 60' and the diameter of the bosh is 10'. The diameter of the throat is 6' and of the hearth is likewise 6'. The depth of the hearth is about 6’ 6". The furnace is producing daily at the present time about 60 tons of pig iron. It could produce more, but because of the present dull market and because of lack of fuel, as the chemical plant from which the company derives its charcoal can give them but enough for 60 tons of pig iron per day, it is unable at present to give-a greater tonnage. The furnace is hand filled. It consumes approximately 93 bushels of charcoal per ton of pig. There are five twyeres, the nozzle diameter of the blowpipe being 4½".

Connected to the furnace are two 3-pass stoves, each one of which is 60' high and 16' in diameter. The blast is heated to from 950° F. to 1,100° F. Stoves are changed every 1½ hours. The blast pressure is 3½ to 4 pounds. The blast is furnished by a Weimer blowing engine which makes from 15 to 17 revolutions per minute. From 7,500 to 8,000 cubic feet of air is supplied to the furnace per minute. For generating power there are 6-250 H. P. water tube boilers of the Wicks type. Blast furnace gas and refuse from the saw mill is used as the boiler fuel.

The charcoal used in the furnace is obtained from the East Jordan Chemical Company. This company have 14-8-cord retort kilns and make the usual by-products from the wood consisting of wood alcohol and calcium acetate. The furnace plant is in no way connected with the chemical plant, but the chemical plant is under contract to supply to the furnace plant a definite amount of charcoal, and this feature assures the furnace company the supply of charcoal necessary for its operation. [From ISIS-1911]

Time Line

Bibliography

The following sources are utilized in this website. [SOURCE-YEAR-MMDD-PG]:

- [AAB| = All Aboard!, by Willis Dunbar, Eerdmans Publishing, Grand Rapids ©1969.

- [AAN] = Alpena Argus newspaper.

- [AARQJ] = American Association of Railroads Quiz Jr. pamphlet. © 1956

- [AATHA] = Ann Arbor Railroad Technical and Historical Association newsletter "The Double A"

- [AB] = Information provided at Michigan History Conference from Andrew Bailey, Port Huron, MI