- Details

- Hits: 3491

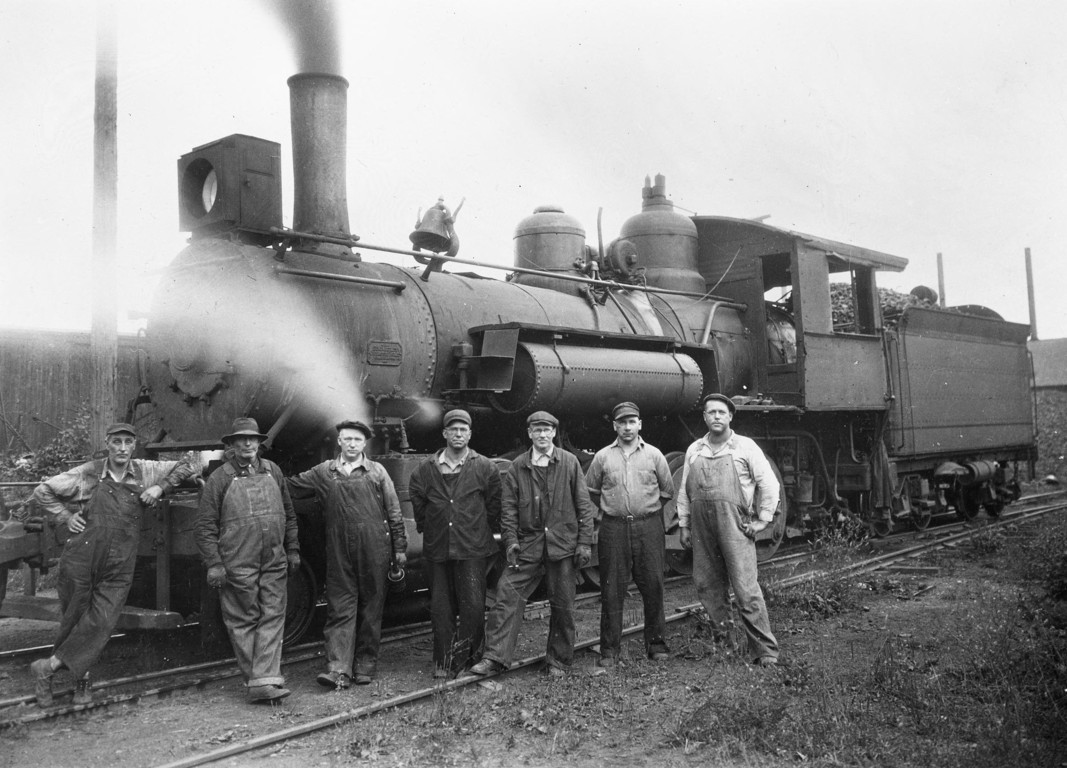

Furnace: Antrim, MI - Antrim Iron Company Furnace

An Antrim Iron Company 2-8-0 with crew works near the company furnace at Mancelona. The furnace was located along the Grand Rapids & Indiana railroad main line to Mackinaw City.

An Antrim Iron Company 2-8-0 with crew works near the company furnace at Mancelona. The furnace was located along the Grand Rapids & Indiana railroad main line to Mackinaw City.

Photo Info: This locomotive is reportedly an ex-Colorado Midland locomotive. [UMB-Stoner Collection]

Notes

1910. Summary of operations. The Antrim Iron Company was organized in Michigan in 1886 with a capital stock of $350,000.00. The officers were W. Bernhardt, President; J. C. Holt, Vice President and Treasurer; H. J. Bennett, Secretary; and N. M. Langdon, Manager.

The furnace was built in 1883 or 1884 by Mr. Otis, who was financially backed by Mr. Cherry of Chicago. On the latter gentleman's failure in 1884-5 the plant went into the receiver's hands, with Mr. Bernhardt as receiver. Mr. Otis, however, was permitted to pull the furnace out of the hole. Mr. T. J. O'Brien was President of the Company from that time until he resigned to enter the United States diplomatic circles as Minister to Japan.

Regarding the furnace proper in1910, it was 60' high and it had a 12' bosh; the diameter of the throat was1' and of the hearth is 6', with a hearth depth of 6'. It was hand filled and is capable of producing 115 tons of pig iron per day; but because of dull market conditions only 80 tons of pig iron was being produced daily in 1910. It had 8 twyeres, and the diameter of the blow pipes at the nozzle of these twyeres was 4 inches. The blast pressure varied from 5 pounds to 7½ pounds to the square inch; an increase in blast pressure of necessity implying an increase in pig iron production. About 6,500 cubic feet of air was blown into the furnace per minute, and an average of 91 bushels of charcoal was used per ton of pig produced.

There was one double Durham iron pipe stove which heated the blast up to about 900° F. There were 18 U-pipes in the stove. There was also a spare stove. The blast was furnished by one vertical Weimer blowing engine, with a piston displacement in the blowing tub of 72" x 48". There were 6-150 H. P. and 2-200 H. P. Wicks vertical water tube boilers. These were both gas fired with waste gases from the blast furnace and wood fired.

The charcoal was obtained from 56, 55-cord beehive charcoal kilns, and 20, 80 cord charcoal kilns of the same type. Wood alcohol and acetate of lime was secured from the volatile matter given forth in the carbonizing of the wood. Connected with the plant was a saw mill wherein the best of the lumber cut is sawed into shape and sold for building purposes. [ISIS-1911]

Time Line

1886. March. The Antrim Iron Company files articles of association. It will operate the Mancelona Iron works. The company is owned by Grand Rapids capitalists. [GRP-1886-0309]

1886. March. The Antrim Iron Co. have purchased 300,000 brick of the Pantlindville brick works, to use in the erection of new kilns. [GRP-1886-0318]

1887. March. The Antrim Iron Company's charcoal kilns at Elmira are turning out an average 18,200 bushels of coal per month. ]DFP-1887-0304]

1886. March 20. The Antrim Iron Company took possession of the Mancelona Iron works yesterday. [SAG-1886-0320]

1887. October. The Antrim Iron Co. paid the GR&I $17,358.77 for freight in August and September. [MUSC-1887-1013]

1886. April. The Antrim Iron Company, a Grand Rapids concern doing business at Mancelona, are building 20 new charcoal kilns at the small towns along the GR&I near Mancelona. [GRP-1886-0409] They expect to torn out 50 tons of pig iron daily. [GRP-1886-0529]

1887. April. The Antrim Iron Furnace Co. of Mancelona, in which a large amount of Grand Rapids capital is interested, are contracting for 30,000 to 40,000 tons of iron ore for use the coming year. The furnace is running full blast. [DFP-1887-0417]

1888. January. Oliver O.P. Hughart, head keeper of the Antrim Iron Company is the son of W.O. Hughart, president of the GR&I railroad. [GRP-1888-0123]

1890. The Antrim Iron Co. is building a new furnace and stack which will double the capacity of the works. [GRP-1890-0228]

1890. May. The Antrim Iron Co. at Mancelona will run two trains daily from the straits (of Mackinaw) to bring to the furnace 100,000 tons of ore from the Lake Superior mines. [FIN-1890-0524]

1892. The Antrim Iron Company employs a large force of men, manufacturing malleable iron and car wheels. [GRE-1892-1218]

1894. The Antrim Iron Co. of Mancelona will shut down the last of this month for ninety days. The company says that all those who remain until they start up can have the rent of their houses for free. [DFP-1894-0514]

1895. April. The Antrim Iron company's furnaces at Mancelona are once more all ablaze after having been shut down a year. This will give employment to 125 men. [YEX-1895-0419]

1895. June 11. The first shipment of ore this season from the upper peninsula to the Antrim Iron Co. amounting to eighteen carloads, passed through Mackinaw City this afternoon. [DFP-1895-0611.

1896. The Antrim Chemical Co., established in 1893, are also manufacturers of refined wood alcohol. Their works are located at Antrim and operated in connection with the Antrim Iron Co. [DFP-1896-1230]

1897. June. The Antrim Iron Co. has cut 2.5 million feet of hardwood lumber at Mancelona. [GRP-1897-0610]

1899. The Grand Rapids Commissioner of the Poor will send 15 men to the Antrim Iron Company in the woods near Mancelona. The company said it will take as many as they can send. Pay is 70 cents per cord and boarding will be provided. [GRP-1899-0314]

1909. February. Grand Traverse county offices are looking for one Bugler Actramey , who is charged with stealing a locomotive and caboose from the Antrim Iron Company roundhouse. Actramey is alleged to have gone to the roundhouse, got the locomotive in shape and started away with it. Twelve persons besides Accasey were on the train. The men were enroute to a small village near here, where it is supposed a cock fight was to have been held. The three-mile trip had only water enough in the tank for a two mile run.

An employee of the Antrim company saw the engine half a mile from the roundhouse, and overtaking it by horse, climbed into the cab and threw Actramey out into the snow. The engine and caboose were run back to the round house and the passengers piled out. Actramey has since been missing. Actramey stole the locomotive, it is believed, because of the fact that no train was running to the spot where the crowd wished to go. Actramey has been employed by the iron company as night watchman of the engine. [SAG-1909-0217][GRP-1909-0217]

1909. August 6. One man was burned to death and another nearly perished when fire destroyed the sawmill of the Antrim Iron Co. at Antrim, one mile south of Mancelona at 11 o'clock this morning. The fire started from an overheated journal on the main shaft under the floor. Loss of $30,000. [DFP-1909-0807]

1909. August 26. The Antrim Iron Co. is building a new branch in addition to its present railroad, northeast of Coldsprings, to reach the Gorham tract of land near the south and east line of Antrim count. The new branch will be about five miles long with two miles laid now. The new road opens up the best tract of timber in this section of the state. [GrP-1909-0826]

1909. November. The work of installing the new machinery in the Antrim Iron Co.'s new sawmill is now under way. A first class outfit consisting of a 500 horsepower Corlis engine, band saw and resaw is being put in. The new mill will have a capacity of 75,000 feet per day and it is expected to be ready for operation January 1st. [GRP-1909-1102]

1911. May. Antrim Iron Co. owner of the furnace plant at Mancelona, has just acquired by purchase, the plant and property of the Antrim Chemical Co. which is located at the same plant. [DFP-1911-0511]

1915. January. The Antrim Iron Co. has commenced work on eight more retorts to be used on connection with its furnace here. This will mean an outlay of $150,000. Since the outbreak of the European war it has been loading acetate which is used in the manufacture of smokeless power. It had several hundred carloads on hand and is shipping 15 to 25 cars daily. [GRP-1915-0123]

1915. Lloyd's (insurance) announces that the British steamer Glenravel of Belfast, has been sunk. The crew of the vessel was landed. The Glenravel was a vessel of 1,092 tons and owned by the Antrim Iron Ore Company of Belfast. [GRP-1915-0809]

1915. October. Thousands of tons of pig iron that has been piled up in the Antrim Iron Co.'s yards, one mile south of Mancelona, is slowly dwindling through shipments made daily over the GR&I. The iron bars are the product of the big smelting foundry that has been the principal industry from which Mancelona and Antrim has benefited for years.

Conditions due to the big war have made possible the shipping to market of the immense quantity of iron that has been stored at Antrim for years. Despite the rumors of the last three or four years that the big company would close its furnace because the market for pig iron was too low, the wheels have been turning just the same and additional ground was used for storage purposes. The foundry is running full capacity. [GRP-1915-1008]

1935. The last large-scale logging operation that the southern peninsula will ever see is going forward. The Antrim Iron Co. is engaged in cutting 7,000 acres of timber, the last large tract of virgin hardwood remaining south of the straits of Mackinac. The company has been working three or four years in this tract and at the present rate of operations will take 5-10 years to finish the job.

The logging operations of this company are a clean cutting proposition. The tops, small trees and poor grade logs go into the manufacture of hardwood chemicals and charcoal, the latter used in smelting iron in the company's factory at Antrim.

The present camp east of Alba is a thoroughly modern one, with electric lights and any other conveniences. Tractors are replacing teams in the woods and the company's railroad, built to the site of the present operations 3-4 years ago, has been abandoned because improved and snow-free roads now make it cheaper to haul logs to the mill by truck year around. [FLJ-1935-1229]

1939. Operations have been resumed at the plant of the Antrim Iron Co. near Mancelona, which had been shut down for the past year. The furnace was put in blast recently, along with the retort and chemical plant, which the acetate plant getting underway this week. [PHTH-1939-0717]

1943. August. Difficulties in obtaining chemical wood because of the shortage of labor, will the cause the Antrim Iron Co. to suspend operations for good this fall, which will leave the Newberry furnace alone in the production of charcoal pig iron. [EDP-1943-0802]

1944. March. The Antrim Iron Co. was ordered by Federal Judge Fred M. Raymond to pay $30,259 in back wages to 600 employees. The judge also issued an injunction against the firm to restrain it from employing children in logging, lumbering and manufacturing operations in violation of minimum age provisions of the fair labor standards act. [LSJ-1944-0314]

1945. April. The end of a colorful chapter of Michigan history is reached this week with the closing of the Antrim Iron Co's. saw mill here. It was the last big sawmill in the lower peninsula. The company produced methanol (wood alcohol), acetate of lie, acetic acid, wood tars, and wood oils in its wood chemical plant. Eight thousand acres of the company's former holdings have been purchased by the conservation department for inclusion in state forests. [SJHP-1945-0417]

1951. The former office of the Antrim Iron Company ay Mancelona burns. It had been sold and used by the Mancelona American Legion Memorial Home. [PNR-1951-0917]

Bibliography

The following sources are utilized in this website. [SOURCE-YEAR-MMDD-PG]:

- [AAB| = All Aboard!, by Willis Dunbar, Eerdmans Publishing, Grand Rapids ©1969.

- [AAN] = Alpena Argus newspaper.

- [AARQJ] = American Association of Railroads Quiz Jr. pamphlet. © 1956

- [AATHA] = Ann Arbor Railroad Technical and Historical Association newsletter "The Double A"

- [AB] = Information provided at Michigan History Conference from Andrew Bailey, Port Huron, MI