- Details

- Hits: 3185

Mine: Chapin Mine, Iron Mountain, MI

Many (see list) → Chapin Mine → Closed

Operated for 55 years.

From: 1879

Location: S 1/2-SW and SW-SE (Chapin); N 1/2-SW Sec. 30 T40N-R30W (Hamilton; N 1/2-SE and SE-SE Sec. 25 of T40N-R31W (Ludington). Ludington included the Bradley Mine (N 1/2-SE Sec. 25 to 1937)

Owned by: Owned by Schleisinger syndicate; then Oliver Iron Mining Co.

Produced: Iron Ore, soft, non-Bessemer.

Method: Underground and open pit. See notes.

Railroad connection: C&NW/MILW to Escanaba dock.

Until: 1934

Lifetime Production: 27,506,868 tons from 1880-1934.

The Chapin opened in 1880 and shipped every year through 1934, except 1932 and 1933. The Ludington opened in 1880 and shipped through 1894. The Bradley shipped from 1937 to 1950. The Hamilton mine opened in 1886 and shipped through 1892. Shipments after 1892 included in the Chapin mine production.

The Chapin opened in 1880 and shipped every year through 1934, except 1932 and 1933. The Ludington opened in 1880 and shipped through 1894. The Bradley shipped from 1937 to 1950. The Hamilton mine opened in 1886 and shipped through 1892. Shipments after 1892 included in the Chapin mine production.

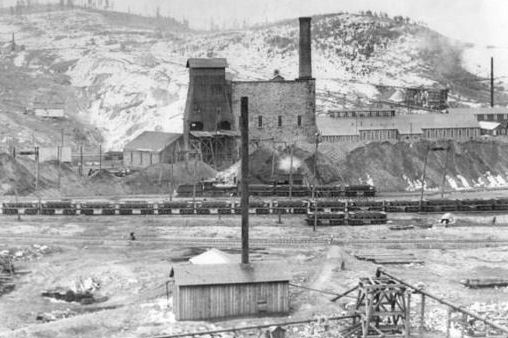

Photo Info: Shaft D of the Chapin Mine in Iron Mountain, turn of the century. [MINARC]

Notes

The property formally was operated by the Oliver Iron Mining Co. Now abandoned and lease surrendered in 1934. Depth: 1,520 feet.

The adjoining Millie Mine (NE-NW and NW-NE Sec. 31 of T40N-R30W) was operated from 1912-1925 through the Chapin Mine workings but is now (1950) a North Range Mining Co. open pit operation. (See Millie Mine). [LSIO-1950]

Hamilton Shaft. The Hamilton Mine was discovered in 1883 and operated by the Hamilton Ore Co. until 1893 when it closed due to flooding. The mine was purchased in 1894 by the adjacent Chapin Mine, and linked by a series of new shafts, pumped out, and reopened. Had boarding house, dry house and machine shop. [UPM]

The Chapin Mine was a large iron ore mine in the middle of Iron Mountain, Michigan. It became a large open pit mine and ultimately a lake. US-141 traverses through the middle of the old Chapin Mine area. As the mine expanded, parts of the surrounding town and north/south rail lines were moved to accommodate mining.

Time Line

1879. Ludington Shaft. The Ludington Mine was opened in 1879 and operated by the Ludington Co. until 1893 and was closed due to massive flooding. It was purchased in 1894 by the Chapin Mining Co. and linked to the nearby Chapin with a series of new shafts and pumped out. It was permanently closed in 1934. It had a Cornish Pumping House (still existing), dry house.

1883. May. The old dry house at the Chapin was entirely consumed Sunday morning. There was a large amount of wire rope in the building which was much damaged. The loss was $2,000 with no insurance.[DFP-1883-0522]

1883. November. DISTURBANCES AT IRON MOUNTAIN, MICH. The strike at the Chapin mine at Iron Mountain assumed an alarming aspect Saturday. Four hundred malcontents approached Superintendent Stockbridge of the Ludington mine and requested an answer to their demands. He refused to yield. He was then thrown down, kicked and knocked around generally, during which cries of "kill him," "hang him," etc., were freely uttered. As soon as he recovered himself he told the men they could have anything they wanted, that they might all go back to work and consider their day's work done at any reasonable hour. The saloon keepers of Iron Mountain have all closed their places and consequently there is no drunkenness'. The local police force is powerless to do anything toward preserving order or quieting any disturbances that may arise, and it is altogether probable that one or more companies of the State militia will be ordered out to preserve peace and protect the property of the county. The Sheriff has been sent for and he will arrive tomorrow morning. [San Francisco Bulletin, November 19, 1883]

1889. The Chapin mine is sold to Ferdinand Schlesinger of Milwaukee, described as the head of "a New York Jewish syndicate". The mine included a large air-compressor plant on the Menominee River which conducts compressed air for three miles through pipes to run the machinery. The ore vein is 3/4 of a mil in length, 140 feeet wide and 1,200 feet deep. [DFP-1889-0208]

1891. Noted to be the second highest producing Bessemer iron ore mine in Michigan. At this time, owned by the Schlesinger syndicate with ore being sent to Escanaba docks via the Schlesinger railroad ore route (later the C&NW ore subdivision). Reported to be shipping five daily trains of fifty cars each. [DFP-1891-0202]

1896. June 15. IRON MOUNTAIN, June 15---An attempt was made Sunday night to kill Captain Martin Goldsworthy and family of the Chapin mine. Two sticks of dynamite were exploded under their house, wrecking the structure badly. Nobody was injured. There have been no troubles at the Chapin mine and the men are apparently contented. It is thought the act was committed by men whom Captain Goldsworthy had refused to employ. [Kalamazoo Gazette, June 19, 1896]

1896. The St. Paul company have removed their side-tracks leading to the Chapin mine. The North-Western will handle the entire output this season, which will increase the shipments from Escanaba very materially. [DD-1896-0415]

1896. August. Wednesday, just before six o'clock, a train of ten loaded ore cars was being let down from the C shaft of the Chapin mine, and at the same time a train of empties was being pushed up from the main track. It was during the hardest part of the rain, which probably accounts for the train men not seeing each other to prevent the collision. The trains met just back of the Chapin mine office, and a bad smashup occurred. One of the locomotives was rolled down the embankment and lay bottom up, while several cars were smashed up and scattered about on both sides of the track. The other locomotive was also considerably damaged. Fortunately the train men jumped in time to save themselves and no one was hurt. The wrecking train was put to work early next morning gathering up the pieces, and the track is now clear. [RTR-1896-0805]

1901 .June 4. Chapin Mine, Iron Mountain, Dickenson Co. - Dynamite explosion causing 8 fatalities.

1907. May. An ore train nearly collapsed into the Chapin pit at Iron Mountain. The slide of the pit occurred at 4:20 am and the tracks dropped 8-10 feet. The engine derailed but did not end up in the pit. The cars stayed on the track. Following instructions the engineer reduced speed as the divide was being approached. While creeping along he noticed the engine sinking. He applied his brakes just in time to save the string of 46 empty cars from a general smashup. It was necessary to transfer the passengers on the westbound trains from Antoine to the depot and vice versa and the same were taken around the loop, depending on the direction in which they were headed, the cross over being made near Norway. [DD-1907-0518]

1911. CHAPIN MINE. The Chapin Mine is located in Iron Mountain, Michigan, and is a property of the Oliver Iron Mining Company, and has been in operation since 1879. The Chapin has three shafts, the “B” Chapin, No. 2 Hamilton, and “C” Ludington. “B” Chapin is at this time idle on account of alterations being made to its hoisting plant. No. 2 Hamilton, since the sinking of “C” Ludington was completed, has been used for hoisting and lowering men and timber only. Pumps are also located on the 12th and 16th levels of this shaft, which, until the Cornish pumping plant was placed in operation, were used for pumping all the coming water in the Chapin Mine.

Since the date of the last meeting of the Institute on the Menominee Range (1905), a few changes have taken place in the way of equipment at the Chapin, which might here be briefly described. The sinking of “C” Ludington shaft has been completed. At this shaft the entire product of the mine is hoisted, and here, also, the greater portion of the pumping from this property is carried on “C” Ludington shaft is 10’ 4” by 21’ 3”; is steel lined and has a depth of 1,522 feet, or is down to what is known as the 17th level. The shaft has two skip compartments, each 5’x6’; one cage, 5’x10’ 4”, and one compartment 9’ 3”x10’ 4”, used for ladderway, pump columns, air lines, electric wires, etc. Two five ton skips are operated in this shaft; the product of the mine being hoisted from what is termed the 14th, or main working level, and which is located 1,201 feet from the surface.

The equipment at “C” Ludington shaft consists of one 34x72 inch single duplex first motion Corliss hoisting engine, operating single drum, 12’ diameter, 10’ face, grooved for 1⅜” rope and is used as a skip hoist, and one 30x60 inch simple reversible Corliss hoisting engine, geared to one 12’ drum, 10’ face, grooved for 1⅜” rope, and used as Cage hoist. Electric generator plant for operating underground electric haulage consists of one 100 K. W. direct current, 250 volt, 400 ampere belt driven generator, driven by 14”x36” Corliss engine, and one two unit, three bearing induction motor generator set, 200 K. W. 250 volt, 800 ampere. The boiler plant consists of four 72”x15’ horizontal tubular boilers. As all the machinery described above is operated with compressed air, this plant is used only in case of emergency.

At this shaft there has also been installed, and is now in operation, a Cornish pumping plant, which, some 15 years ago, was located in “D” shaft Chapin Mine. This plant may be described as a Steeple Compound engine with high pressure cylinders 50 inches diameter, low pressure 100 inches diameter, stroke 120 inches and fly wheel 40 feet in diameter, weighing 160 tons. The pump is of eight-lifts construction, six sets each 192 feet apart and two sets each 170 feet apart. Plungers and discharge column 28 inches diameter, pump rods 7” and 8” diameter. Capacity of pumping plant 3,000 gallons per minute from depth of 1,500 feet. For operation of the pumping plant, there have been installed six 72”x18’ horizontal tubular boilers. The building containing these boilers is one of the standard type of the Oliver Iron Mining Company. [LSMII-1911]

1911. CHAPIN MINE COMPRESSOR PLANT. Mention might also here be made of the Chapin Mine air compressor plant, located at what is known as the Upper Quinnesec Falls, on the Menominee River, about three miles southeast of the mine. This plant was installed in the year 1882. During the years 1903 and 1904, and subsequent to this time, some changes were made in the plant, one of which consisted of building a steel flume to replace the wooden flume originally built. This new flume has a length of 382 feet, is 16 feet deep and 22 feet wide and is supported by 72 concrete piers. New air cylinders of the Corliss valve type, have also been installed, three pair being 34”x60” and one pair 38”x60” in size, replacing three pair 34”x60” and one pair 36”x6o” of the old poppet valve type. Each pair of the cylinders are driven by 50” special double horizontal turbines. A pipe line 24” in diameter, conveys the compressed air to the mine a distance of 16,665 feet. This pipe is built in lengths of 58 feet each, the material being riveted wrought plates ¼” thickness. At the present time, all machinery at the Chapin Mine, with the exception of the Cornish pumping plant, is operated by compressed air. [LSMII-1911]

1927. The Oliver Iron Mining Co. employs 600 men at the Chapin mine in Iron Mountain. The mine has been shipping stock pile. The Ludington is now the production shaft for the engire Chapin Mine. [MCH-1927-0902]